Because of the epidemic, products such as masks and disinfectant wipes have rushed to the front line of the fight against the COVID-19, and for this reason 2020 is being called the year of nonwovens by industry players. All of a sudden, everyone is interested in acquiring, manufacturing and using the nonwovens. A once obscure industry is then suddenly on the front pages of the international news media. They saw this as a good time to do business in the nonwovens sector.

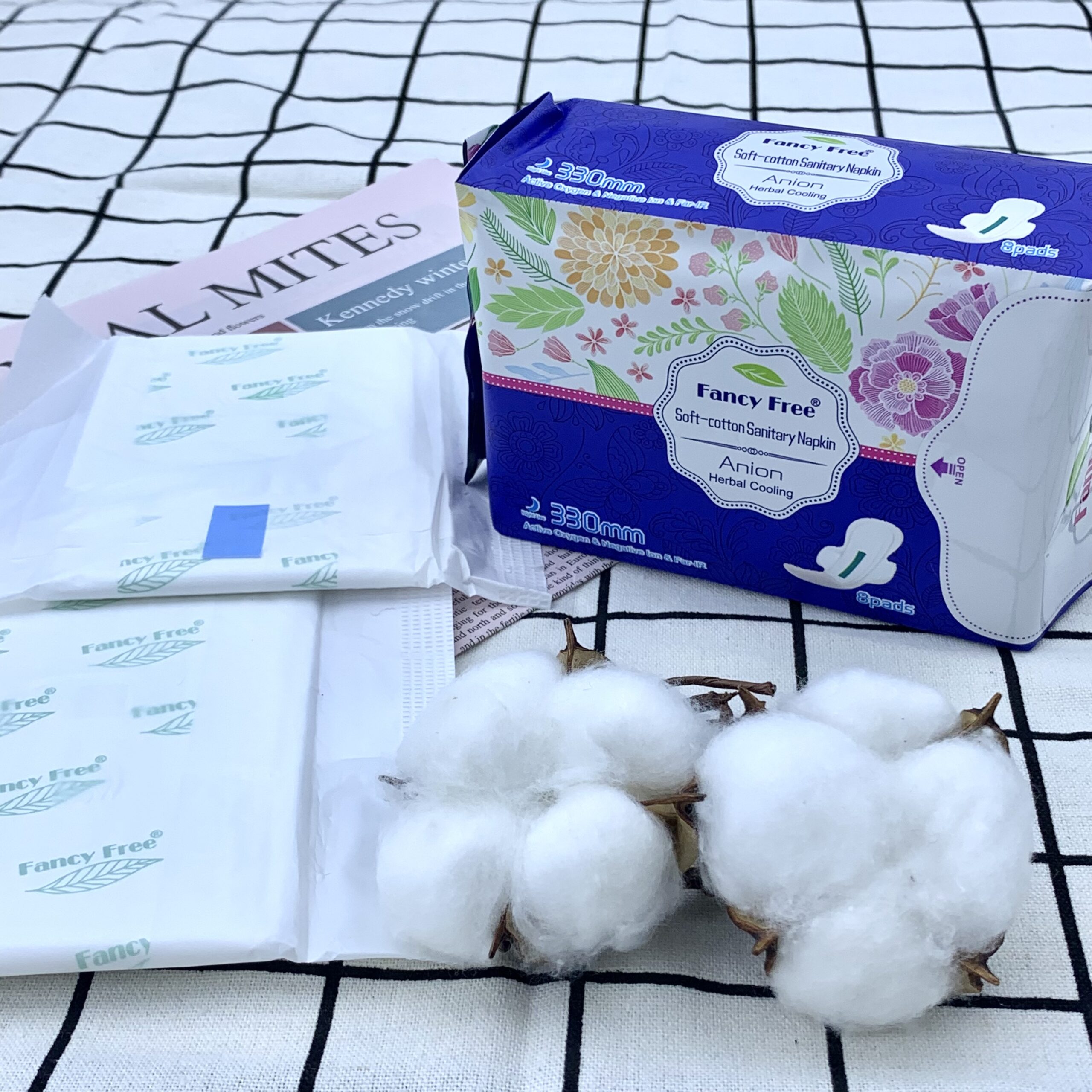

Nonwovens, which is a kind of fabric formed without spinning and weaving, only orientates or randomly arranges the staple fibers or filaments to form a fiber-web structure, and then reinforces it by mechanical, thermal bonding or chemical methods. It breaks through the traditional textile principle and is characterized by a short process, fast production speed, high yield, low cost, wide application and many sources of raw materials. It is used in the medical and hygiene sector mainly for baby diapers, wet wipes, sanitary napkins, etc.

As 2022 draws to a close, it is safe to say that the boom period for nonwovens is over – at least for now. Most manufacturers of both technology and end-use are reporting low utilization of existing lines and investment in new lines has virtually ceased, making the nonwovens industry face an upward challenge. At such times it is up to the nonwovens companies to use this slowdown as an opportunity to focus on attracting new customers through new innovations and technologies.

From the international context, there is still more room and opportunity to expand the international market for nonwovens. The world economy will remain in an upward range in the next few years, which will certainly promote the growth of international trade, bringing a favorable international market guarantee for the growth of the nonwovens industry. Also, as the modern concept of health increases, the frequency of use of disinfectant wipes increases significantly, making the future prospects of non-woven fabrics promising.

Jiayue standard and customized baby/adult/pet diaper, wet/dry wipes, sanitary napkins, under pad, and raw materials. Raw materials include non-woven/SAP/spandex/tape ect.,We have a steady monthly export volume; we have a wealth of experience in exporting and brand development which has helped our customers to become well

known locally.

Why choose us?

- Professional production and sales team with more than 10+ years export experience.

- Skilled loading workers who load more in the container to the sea transport cost.

- Good production capacity and wide products range.

- Skilled salesman with more than 10 years diaper experience.

- Have exported to more than 70 countries, also can help customer marketing the local market.

- Export Volume: more than 100*40HQ/month to all over the world.

- Facilities: Workshops are equipped with the modern machines that are capable of 560 pcs of baby diapers per minute and 230pcs of adult diapers per minute. The R&D department provides strong technical support and enables us to meet the expanding market demand